single shaft plastic shredder

Applications for Plastic single shaft shredder:

- Plastic lump and plastic block, like PP, PE, PET, PC, ABS, Nylon.

- Plastic pipes

- PP/PE film,Woven bags

- Living garbage

- Medical waste

- Electronic Waste

- Copper Cable,Aluminum Cable with steel

- Aluminum cans

- Wood,Pallet,tree root,solid wood etc

Features of High efficiency Plastic crusher / single shaft shredder

1.Single shaft shredder properties as follows:strong, durable.

2.It is suitable to recycle a variety of bulk solid materials,

refractory materials, plastic containers and plastic barrels,

plastic films, fibers, paper.

3.Shredded particles can be small to 20mm according to different

nends. We can provide all kinds of feed hopper.

4.Low speed rotary cutter in accordance with customer needs, which

will be low noisy and energy saving.

Character:

1. this machine is suitable to treat the big size of plastic product

,such as big diameter plastic pipe ,pressing plastic film and

others

2. The blade base and blade on the rotary roller can be disassembly

.it is easy to clean and maintenance.

3. The rotary blade adopt the V design, It can decrease the noise

and decrease energy consumption.

4. Each rotary blade with 4 cutting knife edge, when the rotary

blade is wear, it can be rotated to 90 degree, then the blade can

continues use.

5. Each fixed blade with 2 cutting knife edge, when the fixed blade

is wear, it can be rotated to 180 degree, then the blade can

continues use.

6. The main axis is drive by gearbox, its running very stably, low

noise and strong power.

7. the material push feeding system is hydraulic ways , ,its

running very stably the machine is control by PLC system ,.the

blade can rotated in opposite direction ,and also can close

automatic if something unexpected happen , with very high safety

service.

Model

| WT300

| WT400

| WT500

| WT600

|

Quantity of rotated blade

| 22

| 20

| 24

| 28

|

Quantity of fixed blade

| 2

| 2

| 2

| 4

|

Rotated diameter

| 150

| 220

| 220

| 220

|

Input size

| 300*300

| 400*400

| 500*500

| 600*800

|

Motor power

| 4

| 11

| 15

| 18.5

|

Hydraulic power

| 0.75

| 0.75

| 2.2

| 2.2

|

Weight

| 300

| 1100

| 1100

| 2200

|

L*W*H

| 1200*800*1100

| 1300*1700*2000

| 1300*1700*2000

| 1300*1700*2000

|

Mesh diameter

| 22

| 22

| 22

| 22

|

Motor speed

| 80-100

| 80-100

| 80-100

| 80-100

|

Model

| WT800

| WT1000

| WT4080

| WT40120

| WT40800

|

Quantity of rotated blade

| 46

| 64

| 46

| 10

| 10

|

Quantity of fixed blade

| 4

| 4

| 4

| 2

| 2

|

Rotated diameter

| 400

| 400

| 400

| 400

| 400

|

Input size

| 800*800

| 1000*1000

| 800*800

| 120*120

| 150*150

|

Motor

| 37

| 45

| 37

| 1.5

| 1.5

|

Hydraulic power

| 2.2

| 3

| 2.2

| 0.25

| 0.25

|

Weight

| 3100

| 1500

| 3100

| 3000

| 3000

|

Plastic Lump Shredding Machine/Crate Shredder can be adjusted by

customers' special requirements for throughput volume, material to

be processed etc.

Components:

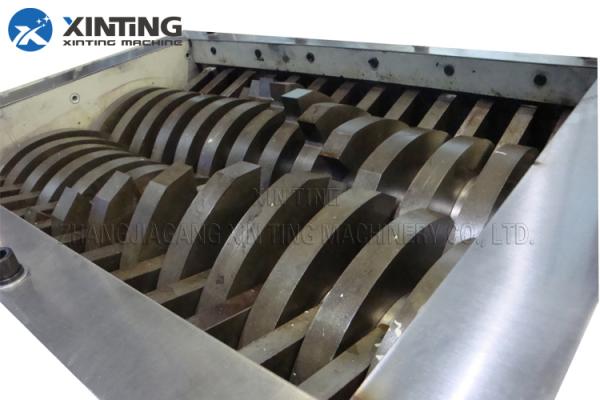

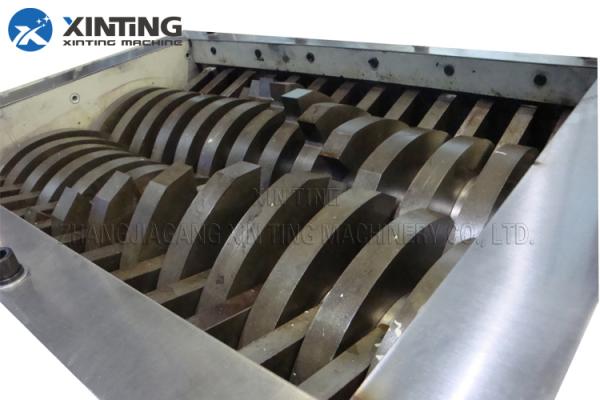

Double shaft shredder

Application Areas:

The shredder machine can easily pre-crush:

•plastic sheets;

•electronic waste;

•scrap (components, subassemblies; consumables);

•metals(lead, aluminum, copper, cable, barrels, sheet scrap, sheet

metal pieces left over from production processes);

•aluminum cans;

•wood(wooden pallets or fruit boxes);

•plastic(plastic bottles or canisters);

•waste tire, rubber;

•waste household appliances;

•paper waste (cardboard, newspaper, office paper, books, magazine,

kraft paper, paper core, cardboard tube, paper packaging material);

•textiles (rags, garments, carpet);

•animal bones and organic waste.

Description:

Double Shaft Shredder with loading hoppers, equipped with high

quality cutters with low rotation speed for a lower energy

consumption and noise reduction. It incorporates two

counter-rotating shafts that intermesh with each other(2 shafts

with sharp elements constituted by sharp-corners disks provided

with hooks); Every hook has the task to hook the product and

drive-it by the action of the two counter-rotating shafts). The

material is powerfully torn and shredded by the talons of the

cuttings discs. Specially designed rotor makes the shredder be

extremely wear resistant.

FAQ

Q:All of your products are made by your self or compacted via

purchasing the others?

A: We have independent technical team who focus on making machines,

all the products are made by our technical team.

Q:Do you have any other services about your products?

A:We have a lot of experience on making projects and specifications

for our clients, also we have a fixed service system.

Q:How do you make the quotation for clients?

A:The price depends on quality and performance but the clients

should be satisfied first.

Q: Are you trading company or manufacturer?

A: We are factory.We have the technical production team,and the

workers are all very experienced.

Q: What kind of certification do you have?

A: Our products have obtained ISO9001 and CE certification,the

quality can be guaranteed.We focus on the field of extrusion

machine,and aim to be the best manufacturer of this field.